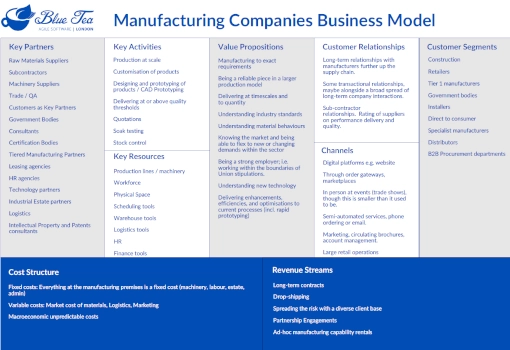

For manufacturers, managing customer relationships, effectively utilising channels and accurately identifying customer segments are paramount for success. Our approach, focusing on a blend of custom and integrated software solutions, positions them to excel in these areas.

Customer Relationships

Our software solutions can facilitate the cultivation and maintenance of long-term relationships with key partners and suppliers further up the supply chain. This includes features for managing both transactional and enduring company interactions, enhancing communication and collaboration. Additionally, our systems could include functionalities for rating suppliers on performance, delivery and quality, thereby ensuring accountability and promoting continuous improvement.

Channels

Blue Tea Software recognises the importance of diverse channels in reaching and serving customers. We design solutions that enhance digital presence through websites and order gateways, enabling manufacturers to effectively utilise marketplaces for broader reach. Our software could also support semi-automated services like phone ordering or email, streamlining order processing and customer service. For marketing and account management, our solutions would facilitate the efficient circulation of brochures and the management of customer accounts, ensuring a consistent and personalised customer experience. While in-person events like trade shows have diminished in prevalence, our software could help optimise these opportunities through event management and follow-up functionalities.

Customer Segments

Understanding the varied customer segments is crucial for manufacturers. Blue Tea Software’s solutions are designed to cater to a wide array of segments, from construction and retailers to Tier 1 manufacturers and government bodies. By providing tailored functionalities, such as specialised modules for installers or direct-to-consumer sales channels, our software can address the unique needs of each segment. For B2B procurement departments and distributors, our systems would streamline interactions and transactions, ensuring efficiency and satisfaction. Additionally, for specialist manufacturers, our software would support niche requirements, enabling them to thrive in their specific market.

By addressing the nuances of customer relationships, channels and customer segments, we aim to empower manufacturers with the tools needed to navigate the complex and dynamic environment of the manufacturing industry. Our future-focused, blended approach to software development and integration ensures that manufacturers are well-equipped to build strong relationships, effectively utilise diverse channels and cater to the specific needs of their varied customer segments, driving success and growth in the process.